Your guide to specialty

materials

Safety gloves are worn in thousands of work environments around

the world in various settings such as bakeries, hospitals and construction

sites. Simply put, safety gloves are protective clothing that provides

protection to the hands, fingers, thumbs, and wrists against external forces,

chemicals, the elements, and workplace hazards. For every industry that

requires safety gloves, there are dozens of different items that offer

specialty specifications for the wearer's needs. In this era of rapid

technological advances, new chemicals are being developed and processes are

being developed. In many ways, workers are exposed to greater risks in their

work environment and having the right safety equipment is important.

Materials

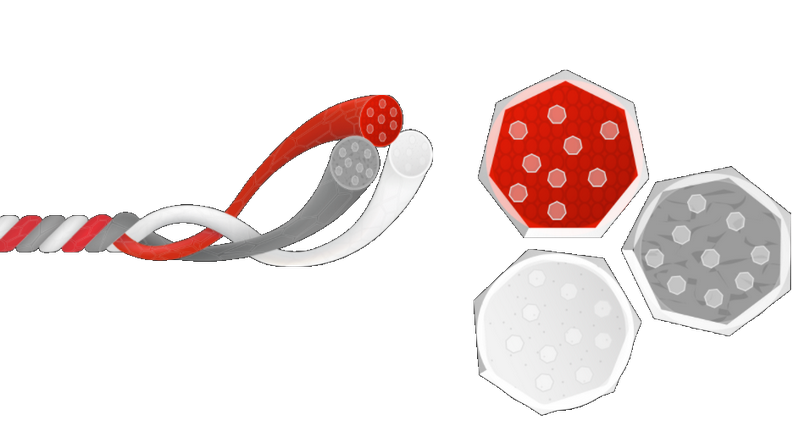

HPPE (High

Performance Polyethylene)

HPPE fiber

has an extremely high resistance to physical-mechanical disturbances from the

external environment, it is also flexible and light, but very durable. Gloves

made entirely of HPPE can typically achieve cut resistance at level 3 / B

according to EN388:2016, but when reinforced with steel or other fiber this can

be increased to cut resistance at level 5 / E and higher .

FIBER GLASS

High

strength to weight ratio and flexibility. Fiberglass is a lightweight material

that creates strength in almost any finished product or component. Fiberglass

can be stronger than steel and metals. Very resistant to the extremes of the

environment, that is why it is used in anti-cut gloves. It has a smooth, silky

surface that feels cool to the wearer, offering high comfort to the user.

Fiberglass can be used as a single component to provide shear strength,

typically reaching level 3 / B, but also to reinforce other fibers.

STEEL FIBER

Compared to

other types of fibers such as carbon, glass, aramid or natural fibers, metallic

fibers have a low electrical resistance. This makes them suitable for any

application that requires electrical conductivity. Their excellent thermal

resistance makes them withstand extreme temperatures. Corrosion resistance is

achieved by using high quality alloys in stainless steels or other metals.

Other advantageous mechanical properties of metallic fibers include high

deformation, ductility, shock resistance and fire resistance. Stainless steel

is commonly used to provide cut resistance in combination with other fibers

such as aramid or HPPE. Cut resistance with steel has been and continues to be

a preferred option for the user,

PolyKor®

PolyKor® Xrystal® is an engineered thread that represents the next

generation in maximum cut protection and comfort. It is a blend of high modulus

polyethylene and mineral based fibers. These mineral-based fibers have a

similar chemical composition to glass, but are inherently better in terms of

resistance to cutting and oxidation, as well as compression and shear.

.Continuous fiber is produced by ingenious extrusion from mineral

melts, creating one of the strongest and toughest fibers in the world.

CARBON FIBER

Antistatic

gloves are made of conductive carbon fibers and coatings that prevent the

build-up of static electricity that, when discharged, can damage sensitive

equipment or create dangerous sparks. Carbon fibers are extremely stiff, strong

and lightweight and are used in many processes to create excellent construction

or protective materials. The properties of carbon fiber are close to that of

steel, and the weight is close to that of plastic. Thus, the strength-to-weight

ratio (as well as the stiffness-to-weight ratio) of carbon fiber is much higher

than that of steel or plastic. Carbon fiber is extremely strong.

Glove covers

Nitrile foam

A layer of

foamed nitrile acts as a sponge when working with oily surfaces, providing

excellent grip in wet and oily conditions. The nitrile in the foam also allows

the hand to breathe, which means increased comfort for wearers. With the open

pore structure of flexible foam nitrile, it can become saturated, so it is more

suitable for oily conditions and dry surfaces.

Fine

textured nitrile

Gloves with

a fine layer of nitrile are tough and durable with good abrasion and puncture

resistance. They typically have a good grip on areas with oil, grease and

liquids, however, they may offer less dexterity, so they are not suitable for

complicated assembly work. Fine nitrile coated gloves work well in a number of

industries including automotive, glass manufacturing, metal fabrication or

stamping and construction.

Polyurethane

(PU)

PU is often

considered the ideal coating for cut protection gloves due to its soft and

stretchy properties that still provide good puncture resistance without being

too bulky. PU coatings tend to have higher levels of penetration into the knit

lining as a disadvantage and this can cause skin sensitivity issues. PU is also

a non-breathable coating, so it is often used as a finger or palm-only coating

style to reduce sweat inside the gloves. PU is durable and flexible, making it

an excellent coating for general sharps handling and assembly in many

industries such as manufacturing, aerospace and precision handling.

Latex

Latex offers

high elasticity and grip compared to other glove coatings. This is especially

true of rough-textured latex, which offers remarkable adhesion often along

puncture resistance. A downside to latex-coated gloves is that latex contains a

protein that can sometimes cause allergic reactions in some wearers. But, latex

is very durable and is still ideal for a number of applications in industries

such as construction, glass, utilities and waste management.

Polyvinyl Chloride

(PVC)

Polyvinyl

chloride (PVC) is a thermoplastic polymer. PVC offers good abrasion resistance

but can be susceptible to punctures, cuts and jams. Although flexible, it does

not offer the tactile sensitivity associated with most rubber products. PVC

begins to soften at about 82°C. PVC is effective against water and most aqueous

solutions, detergents and diluted bases and acids. It has only limited chemical

resistance to organic solvents. PVC is one of the most common coatings for work

gloves.

Thermoplastic

Rubber (TPR)

TPR material, also known as thermoplastic rubber, is a material

that has both plastic and rubber properties. It is lightweight and has good

abrasion resistance, tear resistance, weather resistance and electrical

properties.

Features of TPR material

· It has high flexural fatigue

strength

· High

resistance to tearing and abrasion

· It has high

impact resistance and good dielectric properties

· Resistant to

chemicals

· Recyclable

· It can be

used at temperatures between -30°C and 140°C

Features of TPR material